Engineering Excellence

Discover how we've helped leading Australian companies optimize their operations, reduce downtime, and implement cutting-edge industrial technology.

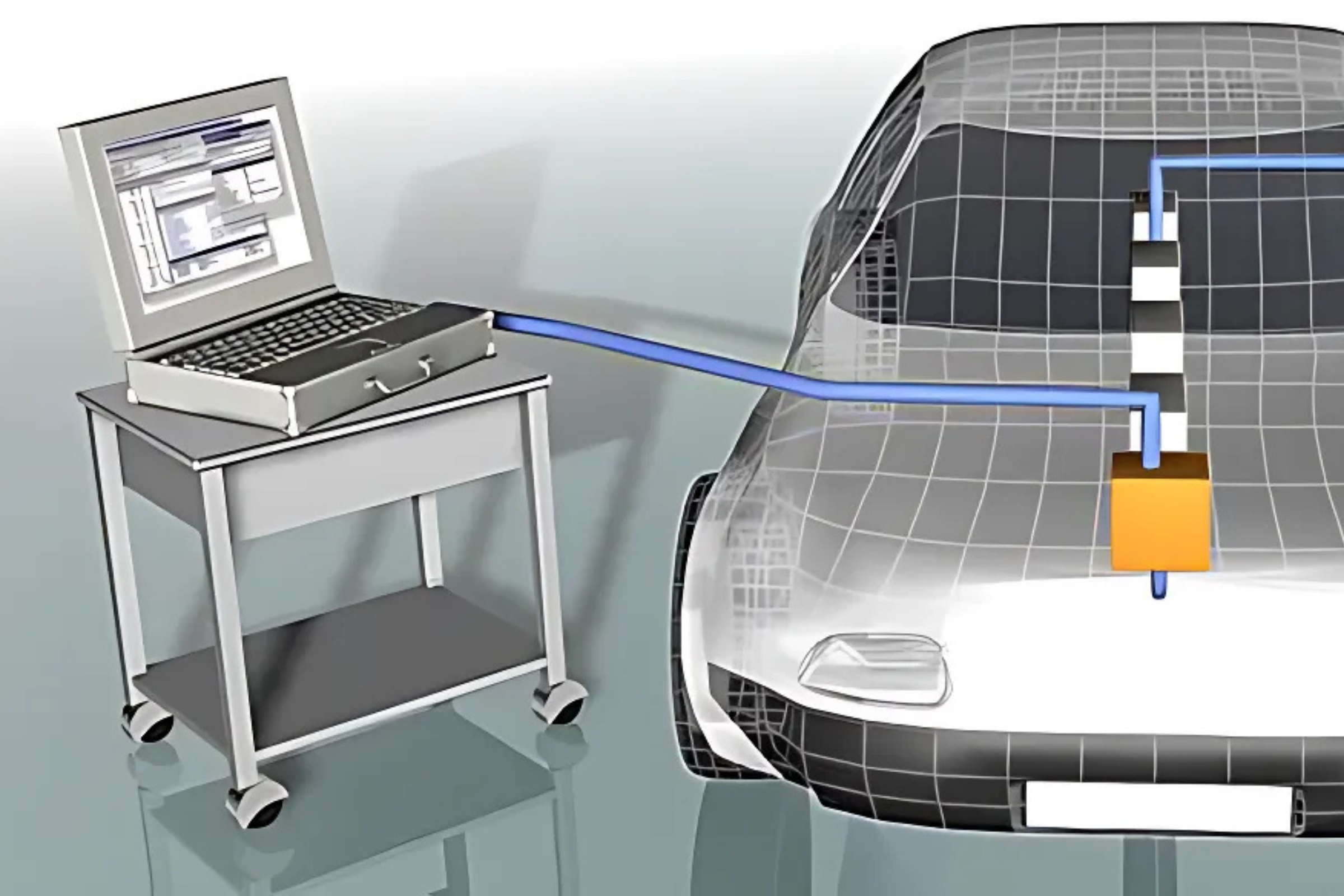

Complete End Of Line (EoL) Vehicle Diagnostic Systems

Ti2 created a complete End of Line (EoL) vehicle diagnostic system for a major auto manufacturer in Australia. Testing system developed with 4Control, an IEC61131-3 product Vehicle ECU communications using Softing DTS7 & EDICusb Interprocess communications utilizing OPC

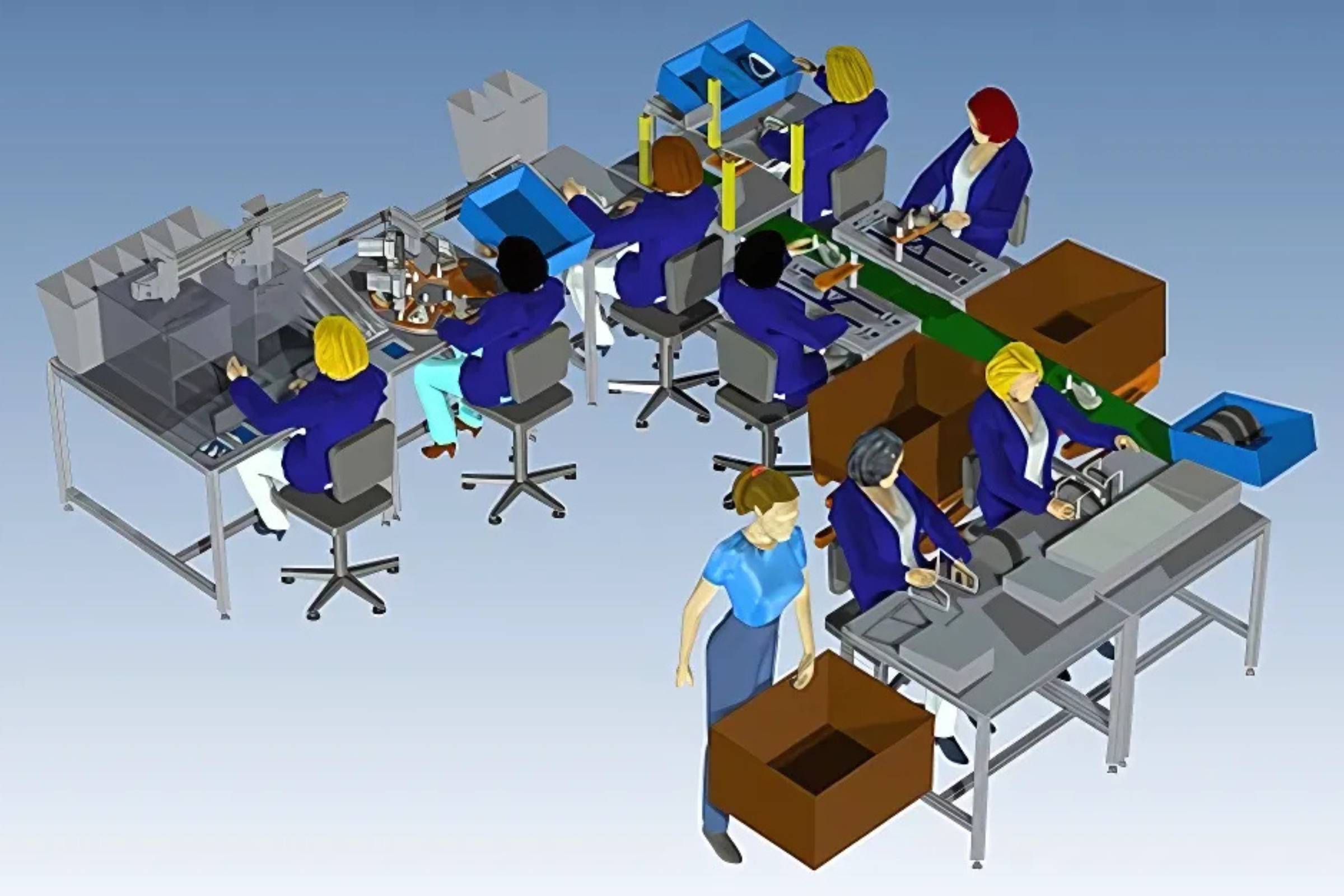

Modernised, Semi-Automated Production Line

Ti2 have completed a modernised, semi-automated production line for an Australian company producing Sleep Apnea products. This project included assembly stations, product flow control, product scheduling, and raw materials management. Supplied with only a one page requirements document and an extremely short time line, Ti2 designed, built, installed, and commissioning a complete semi-automated production line, which included the ability to run multiple sized products, and manage the raw materials delivery and quality control.

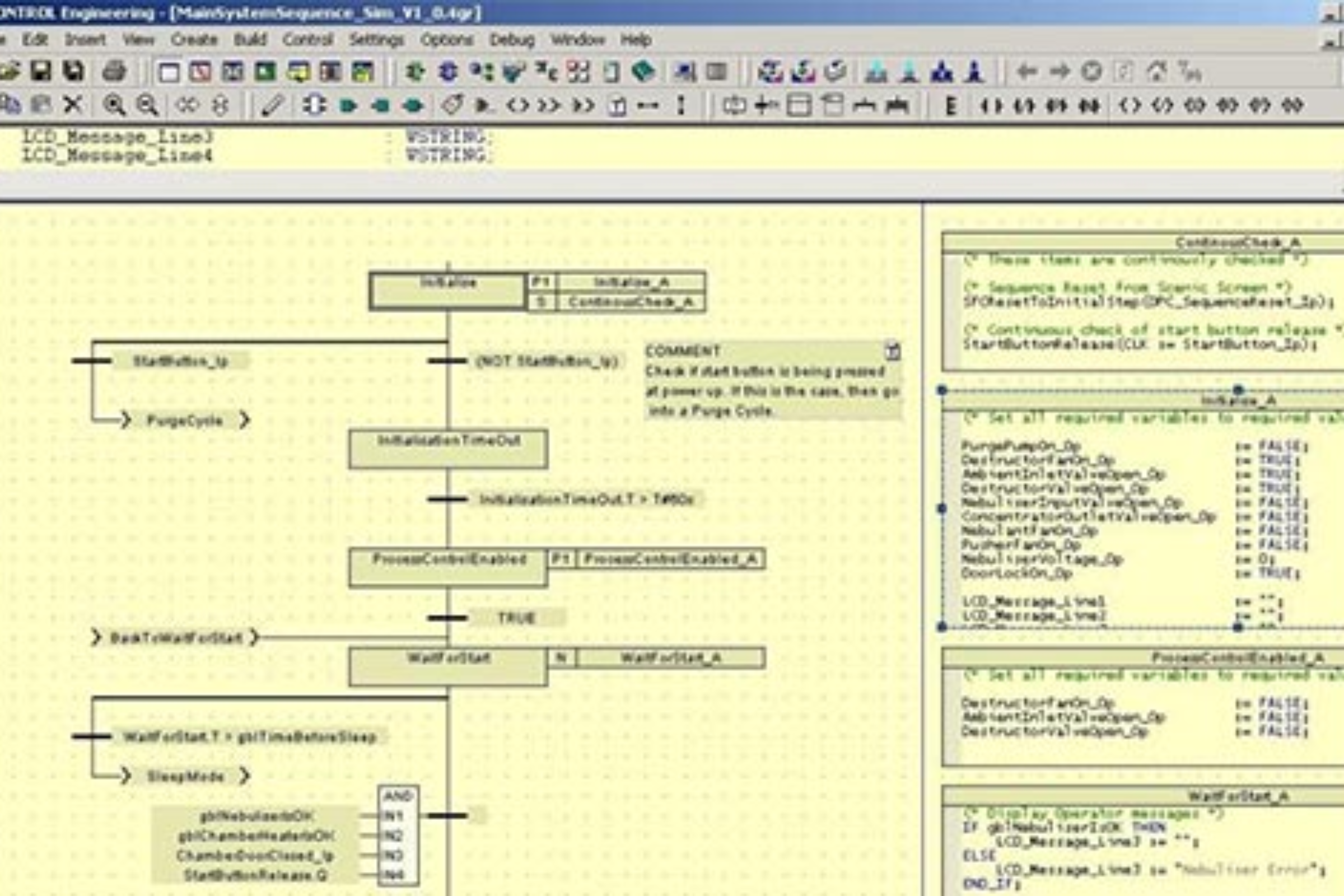

Prototype Controls And Development

Prototype Controls and Development for an Australian Healthcare Company This Australian based company is developing environmentally friendly infection control solutions for the healthcare industry. Initial products include a device specifically designed to disinfect reusable medical instruments such as interactivity and surface ultrasound probes. Ti2 assisted this company on a number of levels including: Electronics, Control Software, and Operator interface development for Prototype units Development of a marketing device Control and Data collection for life testing systems Manufacturing Test Systems – Testing of sub-assemblies and final assemblies

Quality Action – Picture Assisted Selection System (QA – PASS)

Ti2 created a PASS (Picture Assisted Selection System) for a major auto manufacturer to assist operators to select correct tags for the cars on the production line. 4 Control works as an OPC server monitoring specified serial port at all times Coding for different requirements Detailed logs with XML file or database

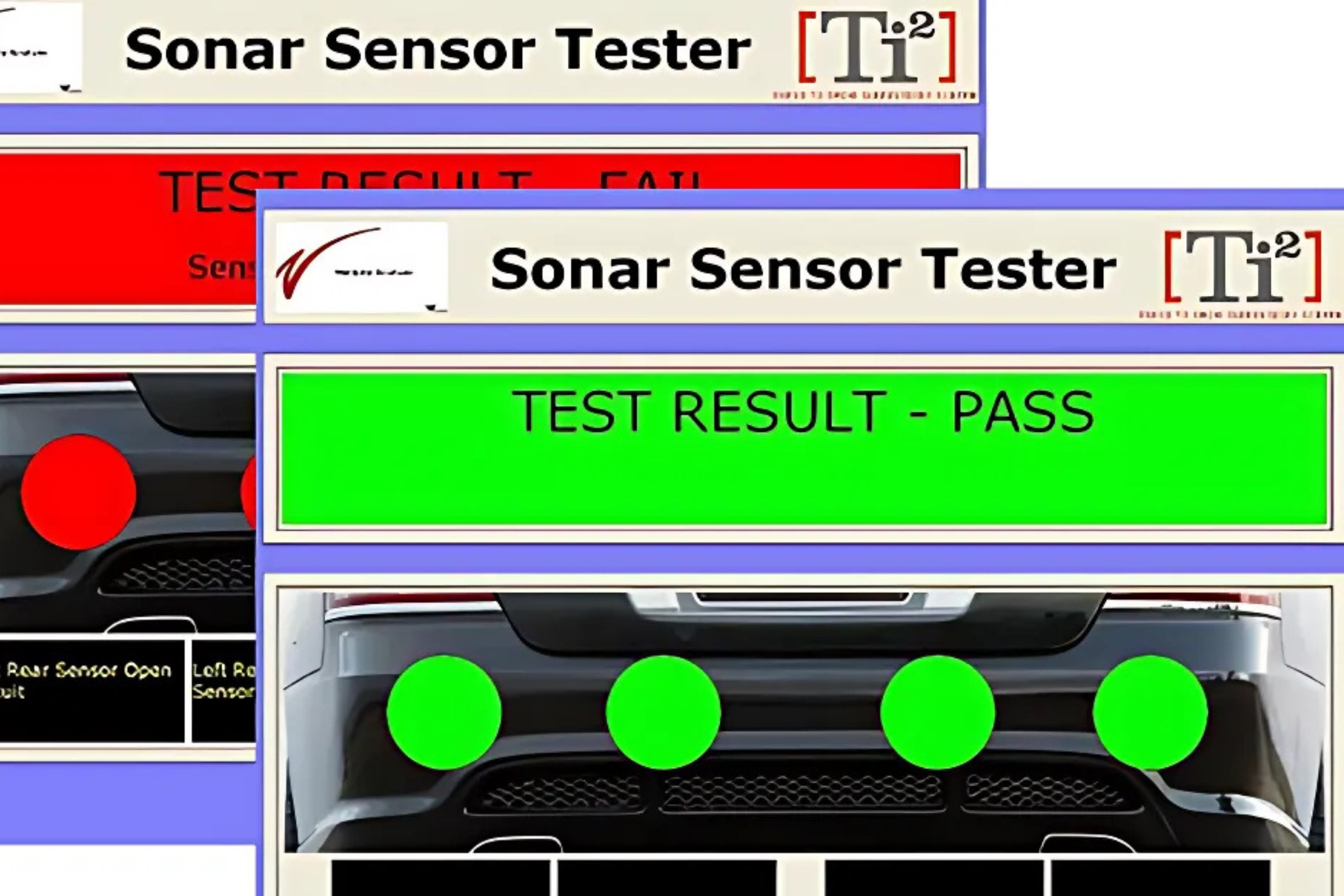

circle background Rear Sensor Sonar Tester For Large OEM

Rear Sensor Sonar Tester For Large OEM Ti2 developed a testing system for a large OEM utilising 4CONTROL and DTS via OPC with an EDICusb as the hardware interface. Requirements were to come up with a simple to use solution that would test the Sonar Parking sensors when installed in the bumper before being shipped to the Ford Assembly plant.

Vision Capture And Analysis Solutions For A Automotive Company

Ti2 have completed a number of vision capture and analysis solutions for an automotive manufacturer. Before the product is ready to ship, a final image inspection is done to determine whether all critical components are installed correctly, and to capture the product bar code. If any of these items are missing, an alarm is raised and the product is not able to proceed down the production line.

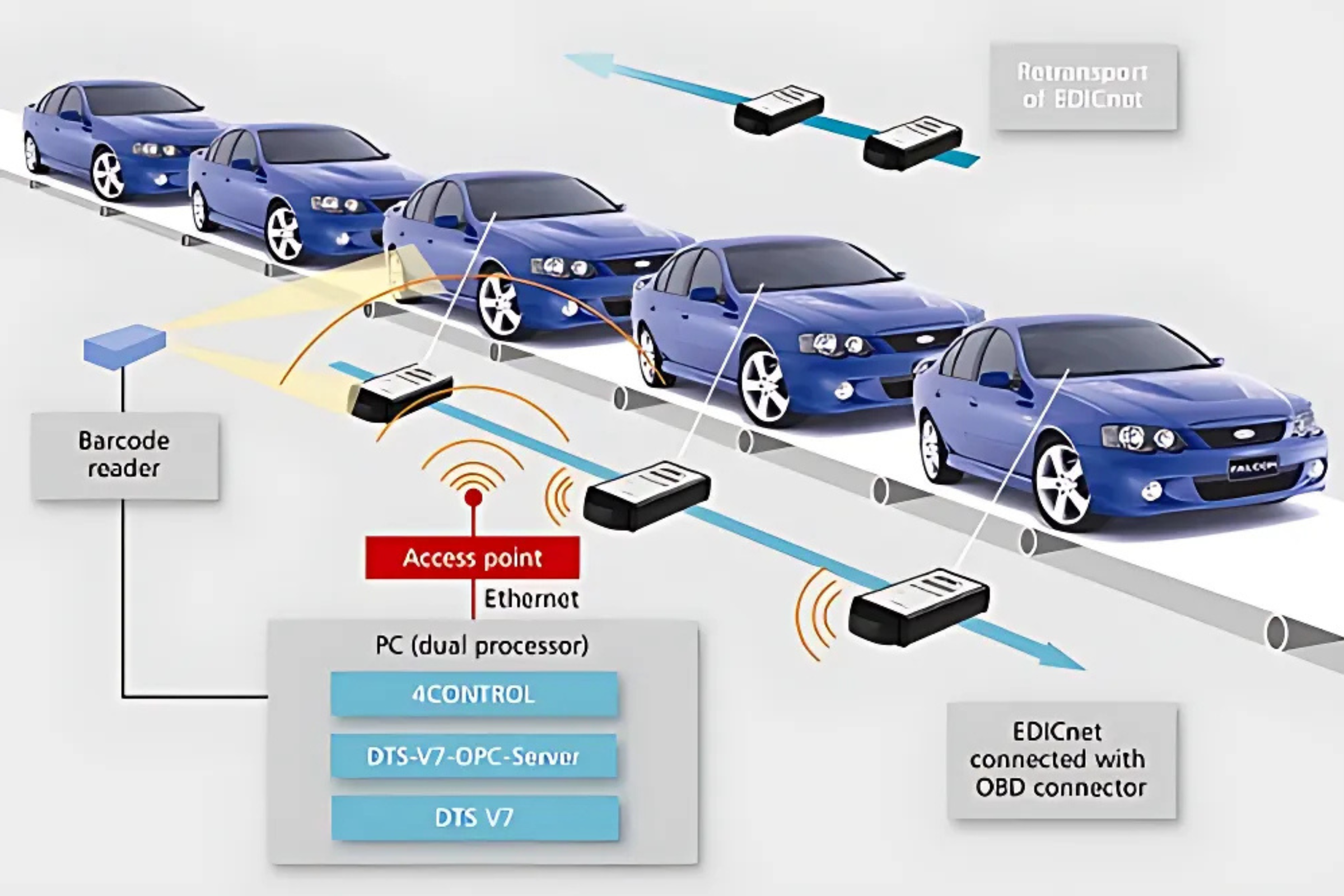

circle background Wireless Programming Of ECUs (SWDL/OSCAR/UCATS

Ti2 was instrumental in helping a major auto manufacturer in Australia to modernise their production line to facilitate wireless programming of vehicle ECUs.

Ready to start your project?

Our engineering consultants are ready to discuss your specific requirements and design a solution that drives performance.